Share to

SH Series Heavy Duty Slurry Pumps

Email:

sales@slurrypump.co

Still deciding? Get samples first, Contact US !

View similar products

Keyword

Warman AH Pumps

Weir Pumps

Metso Slurry Pumps

- Product Description

-

General Introduction:

▶Our horizontal slurry pumps are designed for heavy duty applications such as mining, minerals processing, mill discharge, power plants, tailings and other industrial applications, for maximum abrasion, erosion and corrosion resistance.

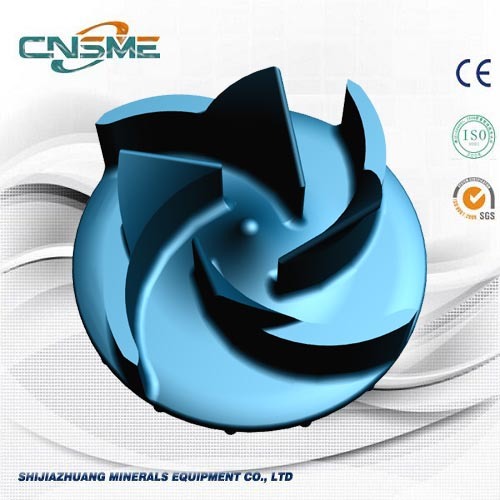

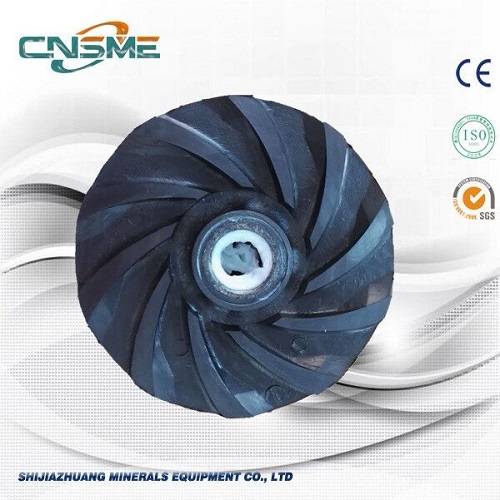

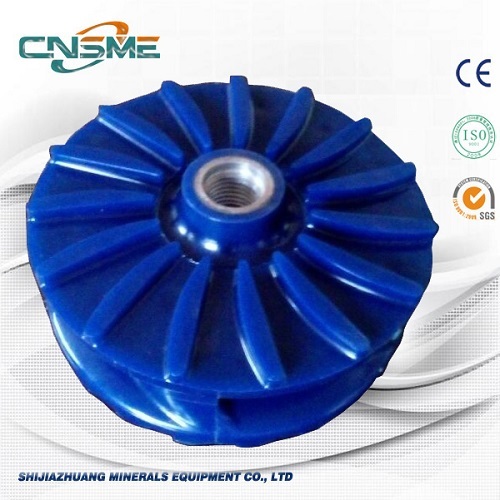

▶The pumps are in a wide range of sizes, available with both high chrome and ruber wearing parts. Components like impeller and volute come in a range of hard metal types and elastomer to suit the specific application.

▶Different shaft seal types are available to suit every requirement, including gland packing seal, expeller seal and mechanical seal.

▶Our metal lined slurry pumps are designed for heavy duty industrial applications, to handle the most arduous slurries.

▶>Wear resistant cast alloys are used for slurry pump liners and impellers where conditions are not suited to rubber, >such as with coarse or sharp edged particles, or on duties having high impeller peripheral velocities or high operating temperatures.

Specifications:

Pump

ModelS×D

(inch)Allowable

Max. Power (kw)Material

Clear Water Performance

Impeller

Capacity Q

Head

H(m)Speed

n(r/min)Max.Eff.

η%NPSH

(m)No. of

VanesVane Dia.

(mm)Impeller

m3/h

l/s

SH/25B

1.5×1

15

Metal

(A05)12.6-28.8

3.5-8

6-68

1200-3800

40

2-4

5

152

SH/40B

2×1.5

15

32.4-72

9-20

6-58

1200-3200

45

3.5-8

184

SH/50C

3×2

30

39.6-86.4

11-24

12-64

1300-2700

55

4-6

214

SH/75C

4×3

30

86.4-198

24-55

9-52

1000-2200

71

4-6

245

SH/75D

4×3

60

245

SH/100D

6×4

60

162-360

45-100

12-56

800-1550

65

5-8

365

SH/100E

6×4

120

365

SH/150E

8×6

120

360-828

100-230

10-61

500-1140

72

2-9

510

SH/150F

8×6

260

510

SH/150R

8×6

300

510

SH/200F

10×8

260

612-1368

170-380

11-61

400-850

71

4-10

686

SH/200ST

10×8

560

612-1368

170-380

11-61

400-850

71

4-10

686

SH/250F

12×10

260

936-1980

260-550

7-68

300-800

82

6

762

SH/250ST

12×10

560

936-1980

260-550

7-68

300-800

82

6

762

SH/300ST

14×12

560

1260-2772

350-770

13-63

300-600

77

3-10

965

SH/350TU

16×14

1200

1368-3060

380-850

11-63

250-550

79

4-10

1067

Applications:

Heavy duty slurry pumping applications

Mining and minerals processing

Mine refuse and tailings

Mill discharge

Cyclone feed

Sand and aggregates

Materials:

Shaft

Shaft Sleeve

Description of Parts

Material

Material Code

Pump Body, Split-Casing

Grey Iron

G20/G21

Ductile Iron

D20/D21

Impeller, Volute,

Wear Liners, Expeller,

Expeller Ring,

Stuffing Box27% High Chrome

A05

15/3 Chrome/Moly Iron

A07

Corrosion-resistant 35% Chrome

A33

28% High Chrome, Low Carbon

A49

Shaft

304 Stainless Steel

C21

316 Stainless Steel

C23

Shaft Sleeve

304 Stainless Steel

C21

316 Stainless Steel

C23

Aluminum Oxide Coating, White

J04

Chrome Oxide Coating, Black

J05

SH Series Heavy Duty Slurry Pumps

Still deciding? Get samples first, Contact US !

View similar products

Keyword

Warman AH Pumps

Weir Pumps

Metso Slurry Pumps

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!