Share to

SF Series Froth Pumps

Email:

sales@slurrypump.co

Still deciding? Get samples first, Contact US !

View similar products

Keyword

Warman Froth Pumps

Metso Froth Pumps

Foam Slurry Pumps

- Product Description

-

General Introduction:

▶SF series froth/foam slurry pumps are SME’s featured products, which are specially used for handling abrasive or corrosive slurries with froth and foam in flotation process . When put into use, SF pumps can efficiently eliminate the froth in the slurries. They can also work normally even when the supplied feedings are not sufficient.

▶The SF froth pump has been designed to increase the pump ability of frothy slurry. The principle of operation is similar to that of hydrocyclone separation.

▶The conical tank design with its tangential inlet creates an open vortex. The vertical inlet prevents air locking by allowing the separated air to rise up along the shaft and exit via the vortex finder.

▶A centrifugal pump is, in general, a very ineffi-cient air pump. Its performance is drastically affected by air containment in liquids. The con-cept behind the conical froth pump is to avoid pumping air and to separate as much air as pos-sible from the slurry before it reaches the pump impeller.

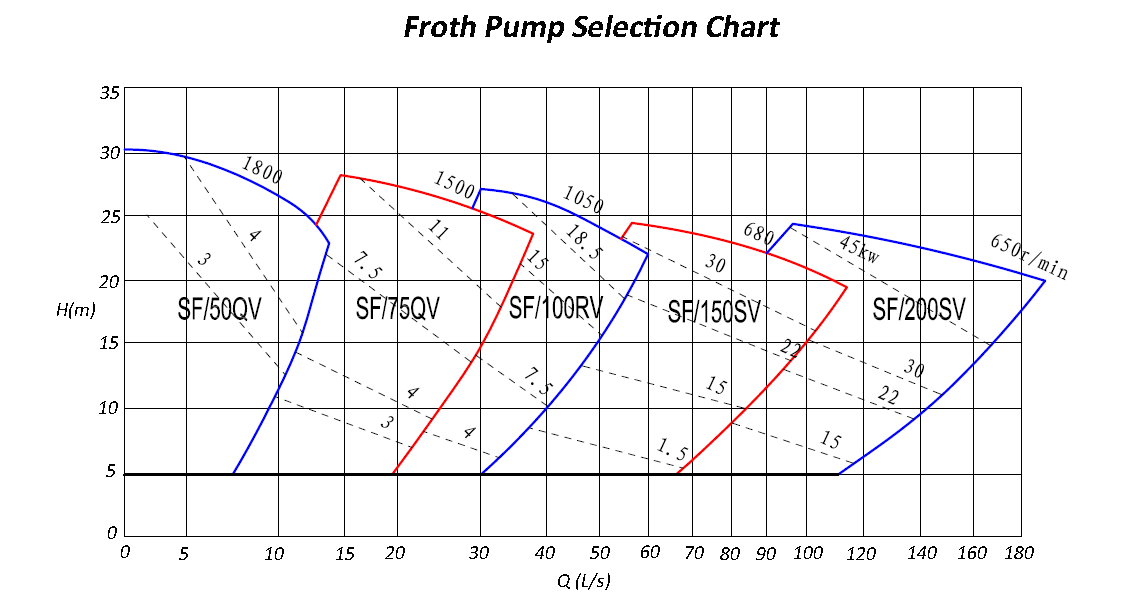

Specifications and Selection Chart:

Outlet: 50mm~200mm

Capacity Q: 7.6~575m3/hr (2.1l/s~160l/s)

Head H: 5~28m

Features:

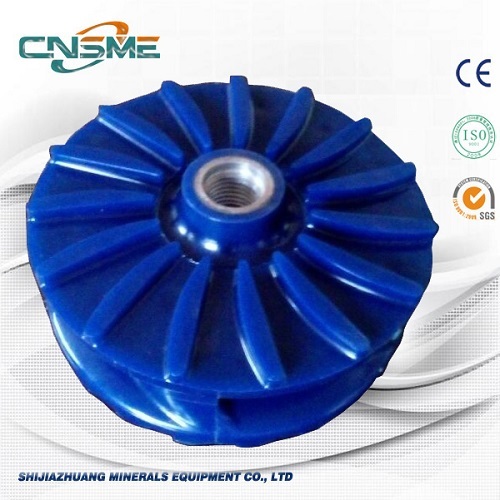

1. Vertical, cantilevered type. Double casing construction.

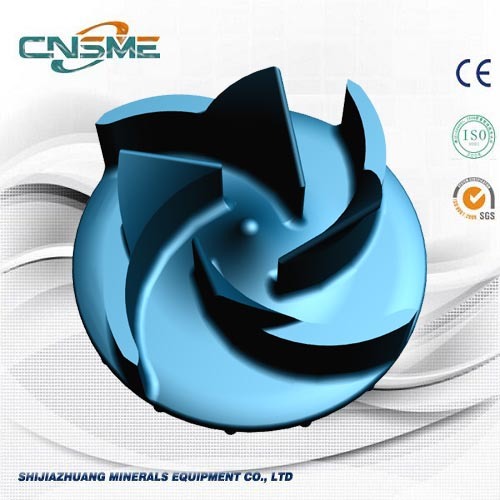

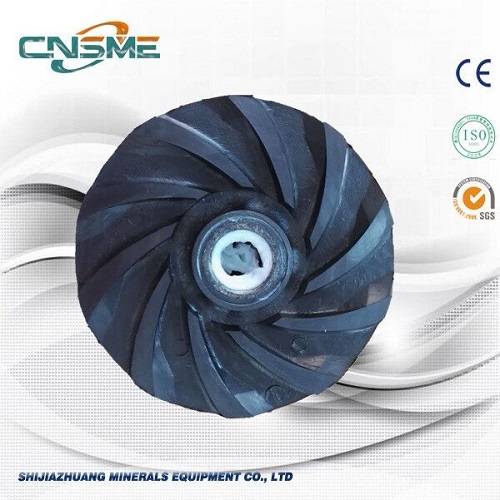

2. Open type impeller, chrome alloy or natural rubber material.

3. Funneling tank, spiral front plate, highly abrasion resistant A05 material. Or changed to rubber to resist corrosion.

4. Cylinder bearing housing, high bearing capacity, grease lubrication.

5. Gap between impeller and front plate can be adjusted to guarantee high efficiency.

6. No bearing seal.

7. Pump and engine can be connected by coupling or V-belts.

Main Parts and Materials:

1. Impeller/Casing/(Spiral)Front Plate: A05, A07, A33, A49 (Impeller is open type).

2. Cover plate/Frame plate/Bearing housing/Base: Grey Iron or Ductile Iron.

3. Shaft: 45# Carbon Steel.

4. Tank: Cast iron, or also can be rubber lined.

5. Bearings: of makes HBR, SKF etc.

SF Series Froth Pumps

Still deciding? Get samples first, Contact US !

View similar products

Keyword

Warman Froth Pumps

Metso Froth Pumps

Foam Slurry Pumps

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!