Share to

High Performance Vertical Slurry Pump

Email:

sales@slurrypump.co

Still deciding? Get samples first, Contact US !

View similar products

Keyword

WARMAN vertical slurry pumps

- Product Description

-

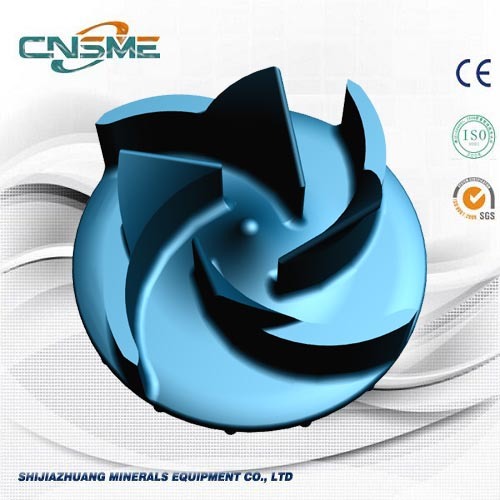

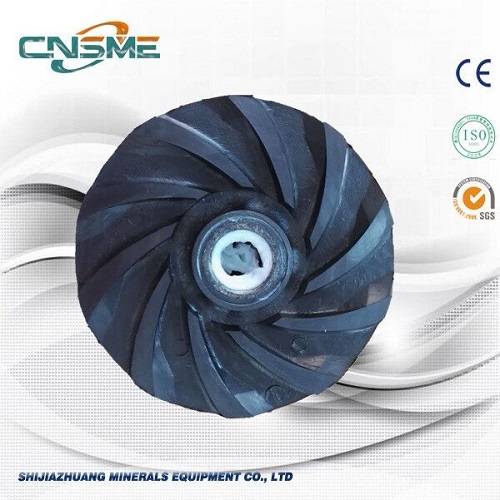

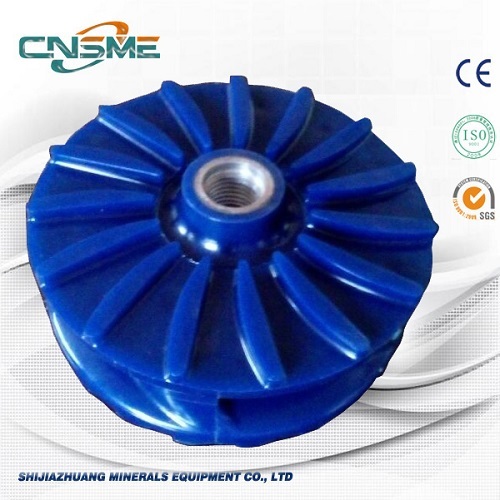

Material: High Chrome Alloy Feature: Low Power Consumption Theory: Centrifugal Application: Sump Drainage Type: Vertical Cantilever Impeller: 5-Vane Open High Light: vertical centrifugal pump

,vertical submersible pump

High Performance Low Power Consumption Cantilevered Sump Pump

Introduction:

The robust and durable range of WARMAN vertical slurry pumps is designed and manufactured to operate in the most testing conditions. Applications include minerals processing, coal preparation, chemical handling, sand and gravel and general tank, pit or hole-in-ground slurry

Details:

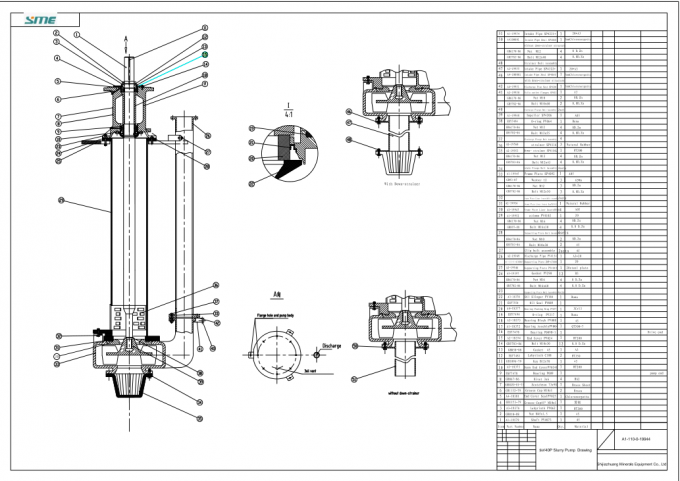

1. Submersible pump is equipped with cantilever, horizontal and vertical axis, double pump case.

2. Double suction and self-open impeller is made of cemented carbide or rubber.

3. China double suction cantilevered submersible slurry pump owns axis components with cylinder shape, and the axis can be lubricated with grease lubrication or oil lubrication according to different requirements.

4. Intervals between impeller and backplate is adjustable.

5. Shaft seal of submersible pump is unnecessary.

6. Pump can be driven by direct connection, v-belt, fluid coupling, and reducer.

7. VS type machine owns components made of rubber which can resist high corrosivity.Specifications:

Model SV-40P Capacity 19.44-43.2m3/h TDH 4.5-28.5m Rated Motor Power 15Kw Speed 1000-2200r/min Max. Efficiency 40% Standard Shaft Length 900mm Materials of Construction:

Part Description Material Casing A05- High Chromium Alloy Impeller A05- High Chromium Alloy Back Liner A05- High Chromium Alloy Shaft Carbon Steel Mounting Plate Mild Steel Strainers Grey Iron Material: High Chrome Alloy A05

Material Chemical Requirements, Weight%

Description Material Name C Mn Si Ni Cr Mo Cu P V S Description Hardness A05 Ultrachrome 2.92 0.98 0.54 0.8 27 ≤0.8 ... 0.062 ... 0.051 27% Cr Erosion Resistant White Iron 58-62HRC

Performance Curve:

Type Size Frame Impeller: SP4206A05 Shaft Seal Frame Rating

(kw)

Normal Max Speed

(r/min)

Max Passage Size

(mm)

SV 40 P 5 Open Type Metal Vans,

Diameter:195mm

Gland Packing, Expeller,

Mechanical Seal

15 2200 12

SV SP Vertical Metal Sump Pump Specifations & Prices Pump

ModelS×D

(mm)Allowable

Max. Power

(kw)Material Clear Water Performance Impeller Capacity Q Head

H(m)Speed

n(r/min)Max.Eff.

η%Length

Shaft (mm)No. of

VanesVane Dia.

(mm)Weight

(kg)Impeller m3/h l/s SV/40P 80×40 15 Metal

(A05)19.44-43.2 5.4-12 4.5-28.5 1000-2200 40 900 5 195 285 SV/65Q 120×65 30 23.4-111 6.5-30.8 5-29.5 700-1500 50 1200 290 432 SV/100R 175×100 75 54-289 15-80.3 5-35 500-1200 56 1500 390 867 SV/150S 240×150 110 108-479.16 30-133.1 8.5-40 500-1000 52 1800 480 1737 SV/200S 320×200 110 189-891 152.5-247.5 6.5-37 400-850 64 2100 550 2800 SV/250T 200 180-1080 50-300 10-35 400-750 60 2400 605 3700 SV/300T 200 180-1440 50-400 5-30 350-700 62.1 2400 610 Material of Metal Lined Vertical Slurry Pump:

No Parts name Materials 1 Shaft 4140 High Tensile Steel* 2 Bearing SKF/Timken(Standard) 3 Bearing Housing HT250 4 Bearing spacer 420 Stainless Steel 5 Bearing SKF/Timken(Standard) 6 Shim 20# Stainless steel 7 Column 20# Stainless steel 8 Strainer QT500-7 9 Back liner 27.5% UltraChrome Alloy 10 Impeller 27.5% UltraChrome Alloy 11 Pump casing 27.5% UltraChrome Alloy 12 Lower strainer QT500-7 13 Discharge pipe 20# Stainless steel 14 Flushing pipe Q235 Carbon steel 15 Coupling 45# Steel 16 Middle supporting parts 20# Stainless steel Sectional Drawing of SV Sump Pumps:

High Performance Vertical Slurry Pump

Still deciding? Get samples first, Contact US !

View similar products

Keyword

WARMAN vertical slurry pumps

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!