Share to

12/10 ST Slurry Pump

Email:

sales@slurrypump.co

Still deciding? Get samples first, Contact US !

View similar products

Keyword

12/10 ST Slurry Pump

6/4 slurry pump

8/6 slurry pump

10/8 slurry pump

- Product Description

-

Introduction:

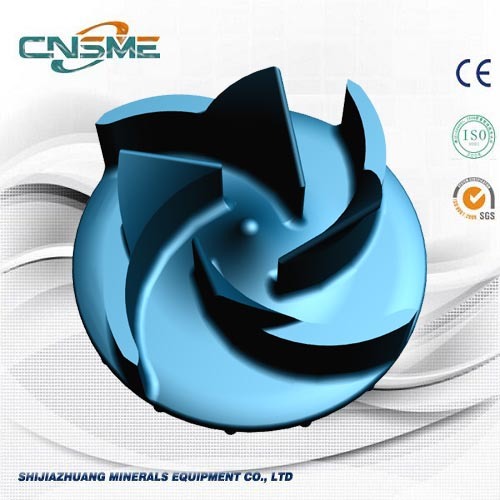

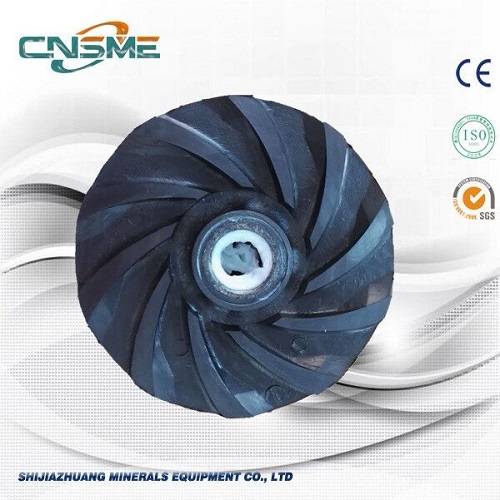

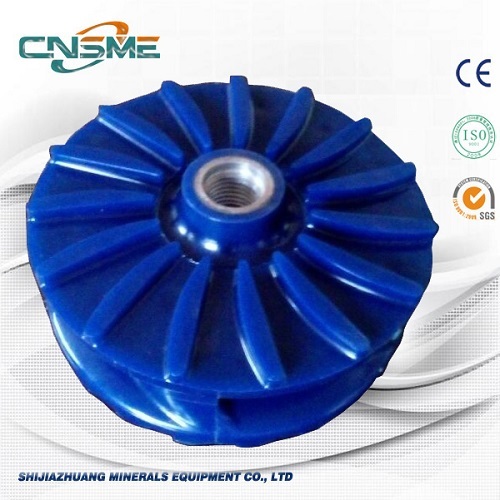

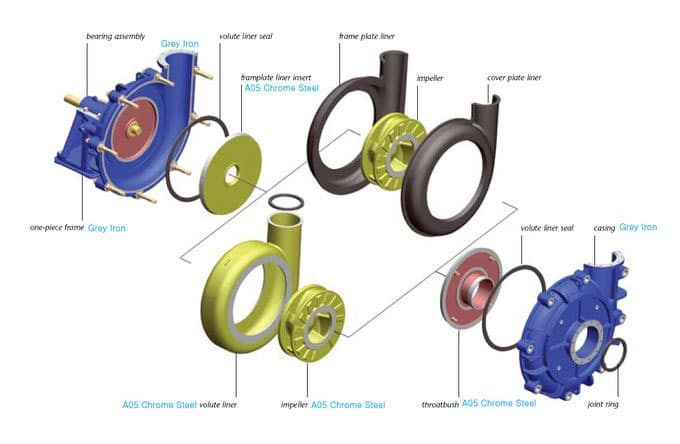

1. CNSME Slurry pumps are designed with double casing, wet-end parts, and rotary parts. Wet-end parts includes volute, impeller, front and back liner. The rotary parts includes the bearing assembly, which are composed of bearing housing, shaft, bearings etc.

2. This is a heavy duty slurry pump that is extremely durable and easy to maintain. It is highly efficient and corrosion and erosion resistant.

It has a long wear life and is extremely cost efficient. The use of effective liners make this pump easy to maintain.

The pump’s many benefits include the bearing assembly, cover/frame plates, suction cover, liners, the impeller, and it has a one piece base.

3. SH-250ST is a slurry pump with discharge size 10 inch.

4. SH-250ST is mostly sold to our customers from Russia, Holland, Italy and other Eastern and Western European countries. SME will always be your reliable partner for quality slurry pumps and pump spare parts.

5. These pumps are characterized by long life, efficient operation and easy maintenance with its low cost.

Pumps are available with either a rubber or a metal lining of abrasive – and corrosion resistant materials. Used bearings for heavy duty, with the increased load on them.

6. Application of SME slurry pumps: mining and processing, mining and metallurgical plants, power plants, cement production enterprises, and diamond-gold mines, technological crushing line, mineral processing, etc.Specifications:

SH Series Metal Slurry Pump Specifications Pump

ModelS×D

(inch)Allowable

Max. Power (kw)Material Clear Water Performance Impeller Pricing Capacity Q Head

H(m)Speed

n(r/min)Max.Eff.

η%NPSH

(m)No. of

VanesVane Dia.

(mm)Weight

(kg)Impeller m3/h l/s SH/25B 1.5×1 15 Metal

(A05)12.6-28.8 3.5-8 6-68 1200-3800 40 2-4 5 152 91 SH/40B 2×1.5 15 32.4-72 9-20 6-58 1200-3200 45 3.5-8 184 118 SH/50C 3×2 30 39.6-86.4 11-24 12-64 1300-2700 55 4-6 214 191 SH/75C 4×3 30 86.4-198 24-55 9-52 1000-2200 71 4-6 245 263 SH/75D 4×3 60 245 363 SH/100D 6×4 60 162-360 45-100 12-56 800-1550 65 5-8 365 626 SH/100E 6×4 120 365 728 SH/150E 8×6 120 360-828 100-230 10-61 500-1140 72 2-9 510 1473 SH/150F 8×6 260 510 1496 SH/150R 8×6 300 510 1655 SH/200F 10×8 260 612-1368 170-380 11-61 400-850 71 4-10 686 3193 SH/200ST 10×8 560 612-1368 170-380 11-61 400-850 71 4-10 686 3750 SH/250F 12×10 260 936-1980 260-550 7-68 300-800 82 6 762 3760 SH/250ST 12×10 560 936-1980 260-550 7-68 300-800 82 6 762 4318 SH/300ST 14×12 560 1260-2772 350-770 13-63 300-600 77 3-10 965 6409 SH/350TU 16×14 1200 1368-3060 380-850 11-63 250-550 79 4-10 1067 10000 Material: High Chrome Alloy A05

Material Chemical Requirements, Weight%

Description Material Name C Mn Si Ni Cr Mo Cu P V S Description Hardness A05 ASTM A532

Ultrachrome 2.92 0.98 0.54 0.8 27 ≤0.8 … 0.062 … 0.051 27% Cr Erosion Resistant White Iron 58-62HRC Construction of SH Slurry Pumps:

Typical Applications:

The primary applications for the SME SH-250ST metal slurry pumps are mill discharge, crusher slurry, sand and aggregate or any coarse solids or other severe, abrasive slurries especially in te copper, gold, iron ore, lead-zinc, coal or phosphate plants.The most dramatic savings will be in these applications, though savings will also be realized on find solids, like fine sand recovery or kaolin. The key advantage of the SH metal slurry pumps is the 10% to 30% lower power, long even wear life and less pump downtime, which results in lowe cost-per-ton pumped, along with better cyclone separation.

Brine Mixture

Sludge and Solids

Sand and Aggregate

Mining Industries

Ash Handling

Cyclone Feeds

Pulp and Paper

Abrasive Slurries

Coal Preparation

Minerals Processing

Aggregate ProcessingCNSME SH Slurry pumps are designed for the toughest slurry applications

CNSME® is a registered trademark. CNSME® Pumps do not represent a registered trademark of Weir Warman and are not affiliated with Warman® in any way. All names, numbers, symbols and descriptions are for informational purposes only and do not mean that any part or pump listed is a product of Weir pumps.

12/10 ST Slurry Pump

Still deciding? Get samples first, Contact US !

View similar products

Keyword

12/10 ST Slurry Pump

6/4 slurry pump

8/6 slurry pump

10/8 slurry pump

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!