Is the slurry pump a centrifugal pump?

May 18,2022

Slurry pumps belong to the category of centrifugal pumps. Slurry pump refers to a kind of machine that increases the energy of solid and liquid mixed medium by means of centrifugal force.

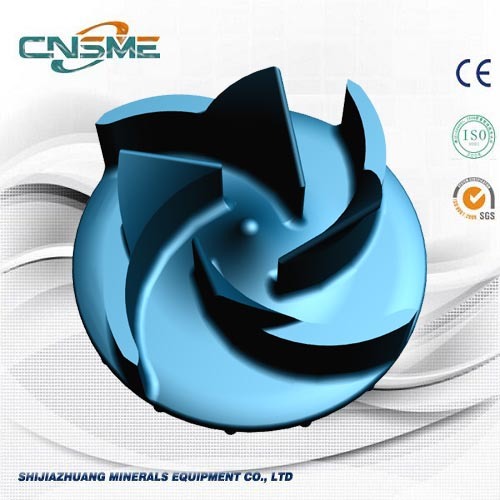

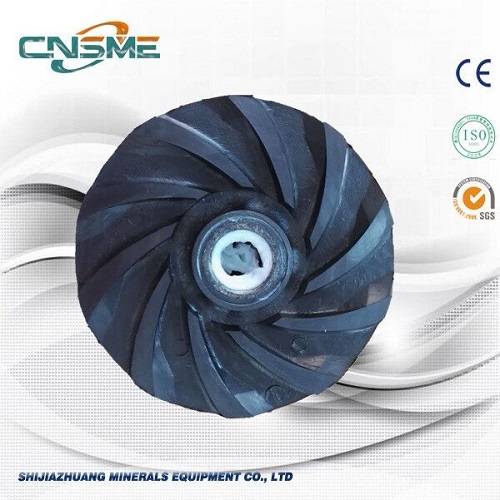

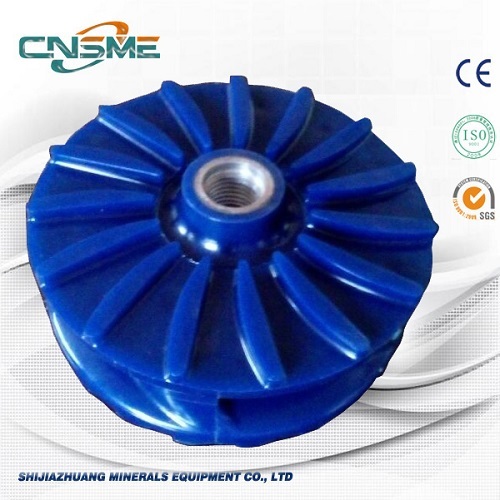

Centrifugal pumps work by rotating the impeller to cause centrifugal motion of water. Before the pump is started, the pump casing and the suction pipe must be filled with water, and then the motor is started, so that the pump shaft drives the impeller and the water to rotate at a high speed. into the pressurized water line of the pump.

The basic structure of a centrifugal pump is composed of eight parts, namely: impeller, pump body, pump cover, water retaining ring, pump shaft, bearing, sealing ring, stuffing box, and axial force balance device.

1. The impeller is the core part of the centrifugal pump. It has a high speed and a large output force.

2. The pump body is also called the pump casing, which is the main body of the pump. It plays the role of supporting and fixing, and is connected with the bracket on which the bearing is installed.

3. The function of the pump shaft is to connect the motor with the coupling and transmit the torque of the motor to the impeller, so it is the main component for transmitting mechanical energy.

4. The sealing ring is also called the leakage reducing ring.

5. The stuffing box is mainly made of stuffing, so that the water flow in the pump does not flow to the outside and the outside air does not enter the pump. Always maintain a vacuum inside the pump! When the friction between the pump shaft and the packing generates heat, the water seal pipe is used to inject water into the water seal ring to cool the packing!

6. Axial force balance device. During the operation of the centrifugal pump, since the liquid enters the impeller under low pressure and flows out under high pressure, the pressure on both sides of the impeller is unequal, resulting in an axial thrust directed towards the inlet. It will cause axial movement of the rotor, resulting in wear and vibration, so an axial thrust bearing should be installed to balance the axial force.

Related Posts

Contact Us

E-mail:

sales@slurrypump.co

Tel:

+86-311-66692398

+86-13333119820

Address:

260# Huai'an West Road Shijiazhuang, 050000, Hebei, China